Practice-based research and implementation

Open-field test stand at Ton Duc Thang University

An open-air test stand was set up on the campus of Ton Duc Thang University and equipped with measurement technology by the project partner Fraunhofer Institute for Building Physics in collaboration with the University of Stuttgart/University of Applied Sciences Lübeck. The field test stand was installed as a measurement container and similar to a measurement container north of Hanoi from the parallel BMBF CLIENT II project CAMARSEC. The CAMARSEC and REBUMAT projects thus provided similar research infrastructures in North and South Vietnam.

Measurement container, open field test stand on the campus of Ton Duc Thang University in HCMC, Vietnam

Results of Outdoor Test Stand and Installation of Measurement Technology

The extensive measurement technology, including the weather station, was jointly assembled in the electronics laboratory of the Fraunhofer IBP in Stuttgart together with employees of the University of Stuttgart and the temperature and humidity sensors were pre-installed as a plug-and-play system. After being transported to Vietnam, the measurement technology was put into operation on site in the basement of the TDTU and the staff were trained.

| Wall Section | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Main Material | Hollow clay brick | Foam glass concrete block | AAC lightweight concrete | Foam glass concrete block | Rammed earth with geopolymer | Typha panels | SGW cement board | Bio-based lightweight wall |

| Width [m] | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Adhesive | Jobsite mix | MU-301 | Jobsite mix | To be defined | To be defined | See next slide | According to SGW specification | To be defined, see next slide |

| Exterior Plaster | — | MU-301 | — | — | — | — | — | — |

| Layer 1 | — | MU-200 | — | — | — | — | — | — |

| Layer 2 | MU-110 | MU-110 | MU-110 | MU-110 | tbd | tbd | MU-110 | tbd |

Test walls and installations in the field test facility at the TDTU in HCMC

Construction Installation of test walls in the field test stand, a 12 m long measuring container, at the TDT University in Ho Chi Minh City. On display is the magenesite-bonded Typha wall, developed by Fraunhofer IBP, a rammed earth wall from TDTU and a wall section made of cellular glass concrete blocks from the Vietnamese Institute for Building Materials VIBM.

Installation of the extensive measurement technology with weather station, temperature and various humidity sensors for the long-term measurement of 8 test walls in the test stand of the Ton Duc Tan University in HCMC. The installation of the measurement technology, commissioning and training took place in a laboratory at the university.

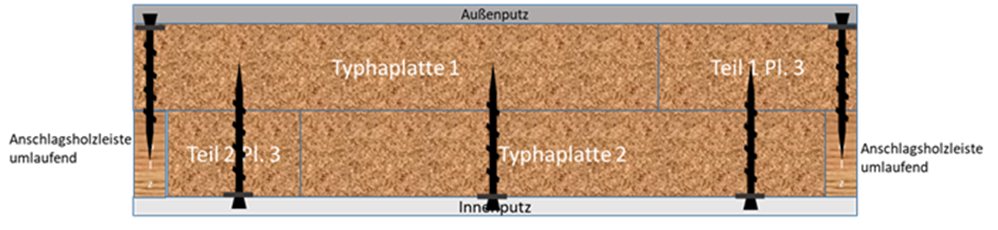

For the installation of Typha plates in the test rig in HCMC, special magnesite-bonded Typha plates were manufactured in Germany and sent to HCMC with installation instructions: The thickness of each panel is 10 cm. The panels on the outside are screwed to the wooden connecting strips. Screws with the largest possible thread and a wide washer are used for this. The inner panels are then screwed to the outer panels from the inside (or glued if necessary). Plaster is then applied to the inside and outside. The plaster can be the typical building site plaster used in Vietnam.

Assembly and installation instructions for installing the Typha building panels in the outdoor test stand for long-term testing under real climatic conditions.

Going back to project outputs